Siloxane Masterbatch

What is Siloxane Masterbatch?

Siloxane masterbatch is a high-performance plastic additive engineered to enhance the processability and surface properties of thermoplastics during manufacturing. It consists of siloxane-based polymers typically polydimethylsiloxane (PDMS) uniformly dispersed in a carrier resin such as polyethylene (PE) or polypropylene (PP). This masterbatch is widely used in injection molding, film extrusion, wire and cable coatings, and automotive plastic components where precision processing and superior surface finish are critical. When added to base polymers, siloxane masterbatch significantly improves melt flow, reduces friction and die build-up, and facilitates excellent mold release. It also enhances the final product’s surface smoothness, scratch resistance, and anti-stick performance, making it ideal for high-speed production environments. Additionally, it supports energy-efficient processing and maintains the mechanical strength, dimensional stability, and color of the plastic material. Because of its versatility, siloxane masterbatch is a preferred solution for industries focused on advanced polymer processing, plastic product quality, and manufacturing efficiency.

Key Features

Related Products

Airbag

AC Knob

Window Quarter Panel

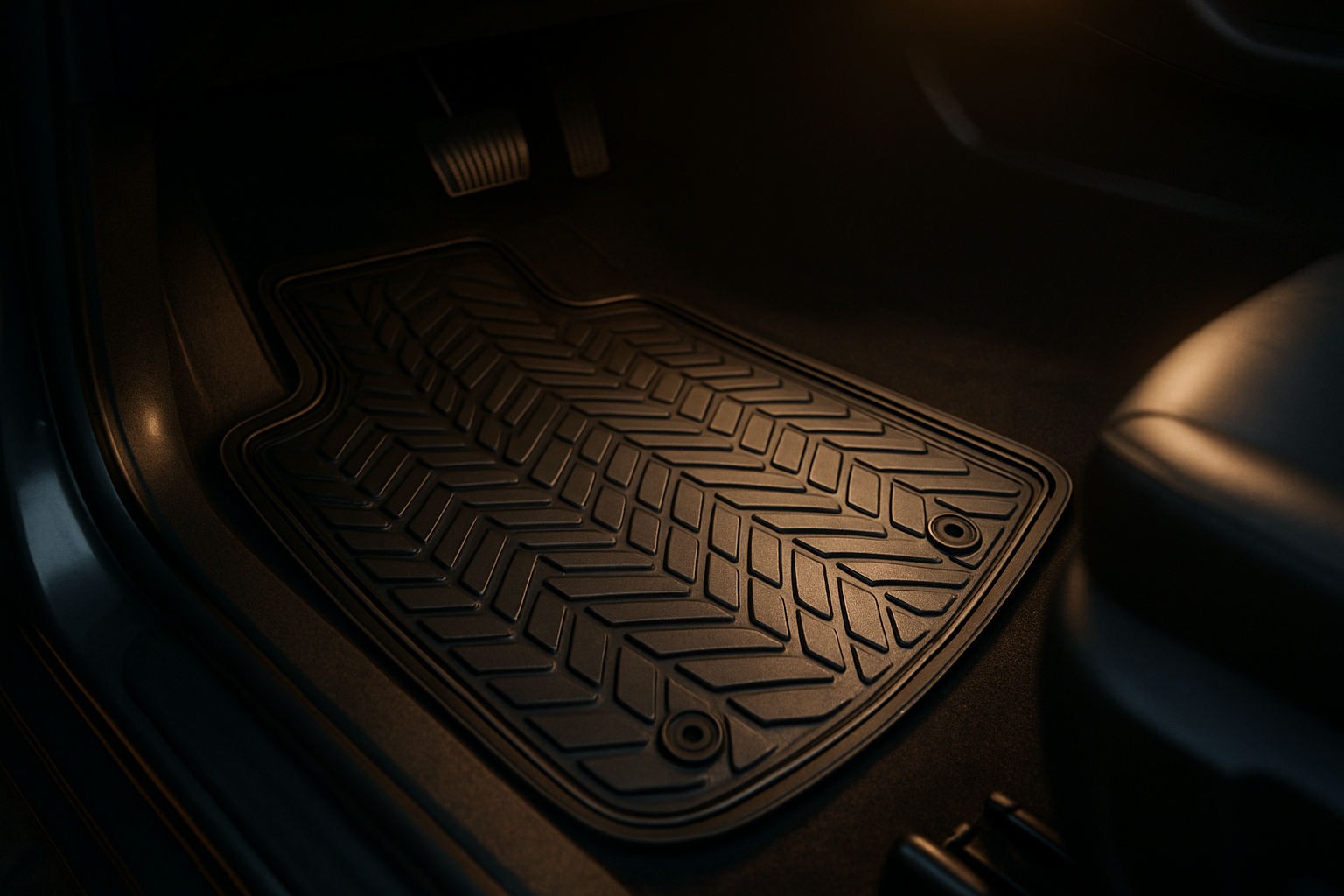

Car Interior

Plastic Gears

Electrical Cables

PLB Conduit Pipes