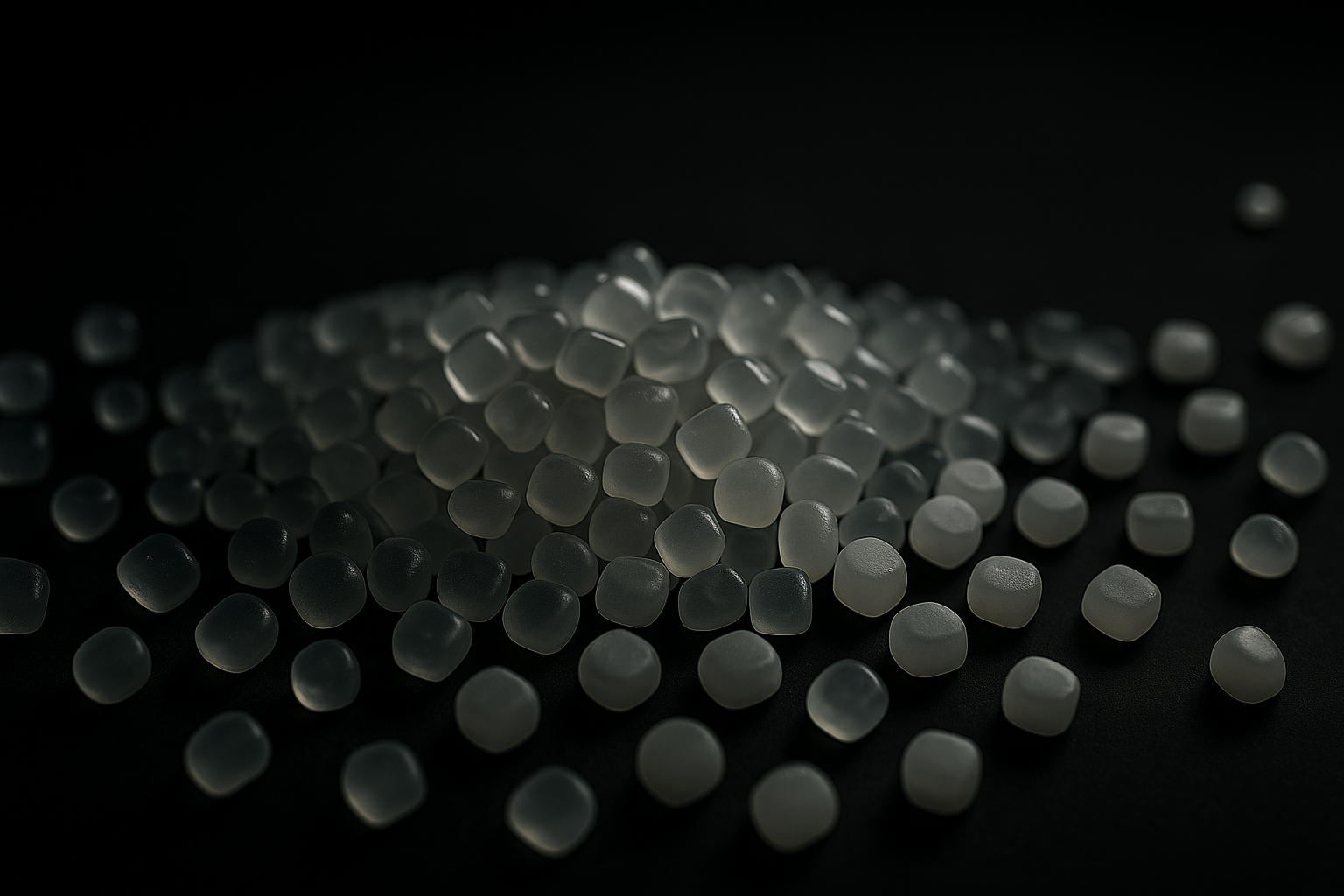

Thermoplastic – Elastomer

What is Thermoplastic – Elastomer?

Thermoplastic Elastomer (TPE) is a high-performance, flexible polymer material that combines the elastic behavior of rubber with the processing efficiency of thermoplastics. As a soft-touch, moldable, and recyclable material, TPE offers exceptional versatility for a wide range of applications. This thermoplastic rubber can be easily processed using conventional methods such as injection molding, extrusion, and blow molding, enabling fast and cost-effectivYKnown for its durability, chemical resistance, and UV stability, TPE is widely used across automotive applications (such as seals, trims, and airbag covers), medical-grade components, consumer electronics, and industrial parts. Its ability to maintain elasticity under stress, along with its soft, tactile finish, makes TPE an ideal solution for both functional and aesthetic product designs.

Key Features

Related Products

Blinker’s Stay

Fuel Door Seal

AC Vent