Siloxane MasterBatch

Siloxane masterbatch is a high‑performance additive designed to improve the processability and surface properties of thermoplastics during manufacturing operations.

What is Siloxane Masterbatch?

- Siloxane masterbatch is a high-performance additive designed to improve the processability and surface properties of thermoplastics during manufacturing operations.

- It is composed of polydimethylsiloxane (PDMS)-based siloxane polymers, uniformly dispersed in carrier resins like polyethylene (PE) or polypropylene (PP), ensuring compatibility with a wide range of thermoplastics.

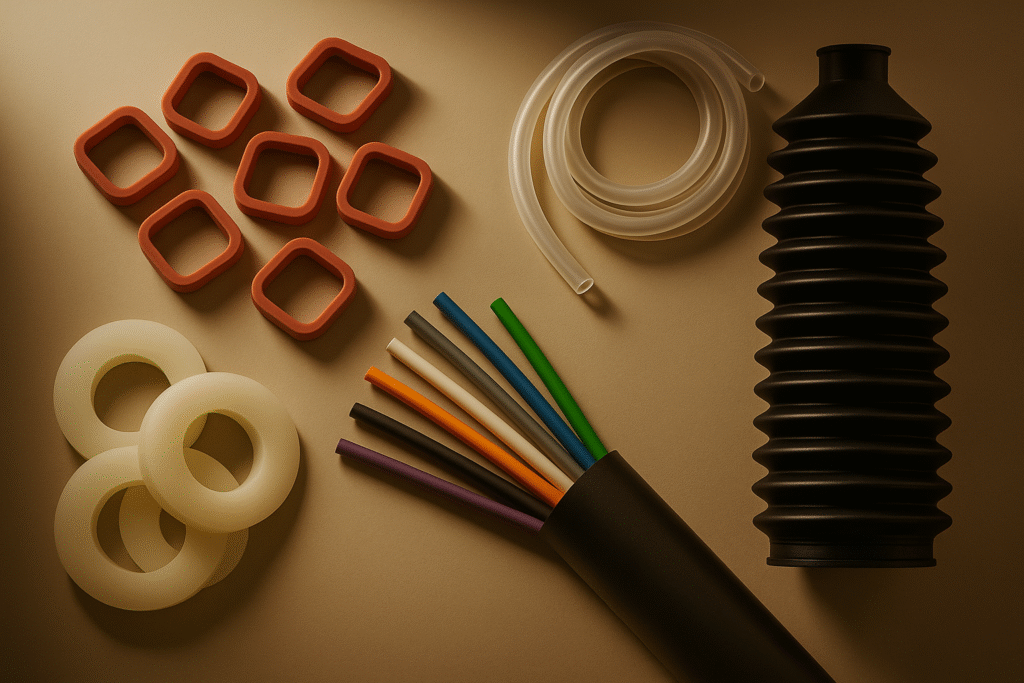

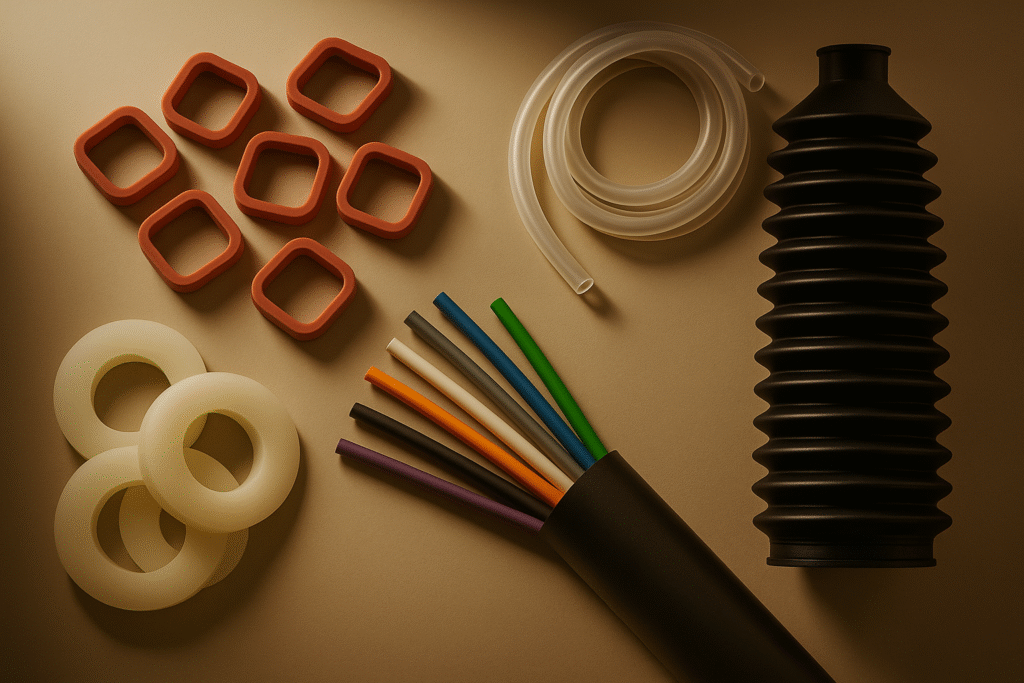

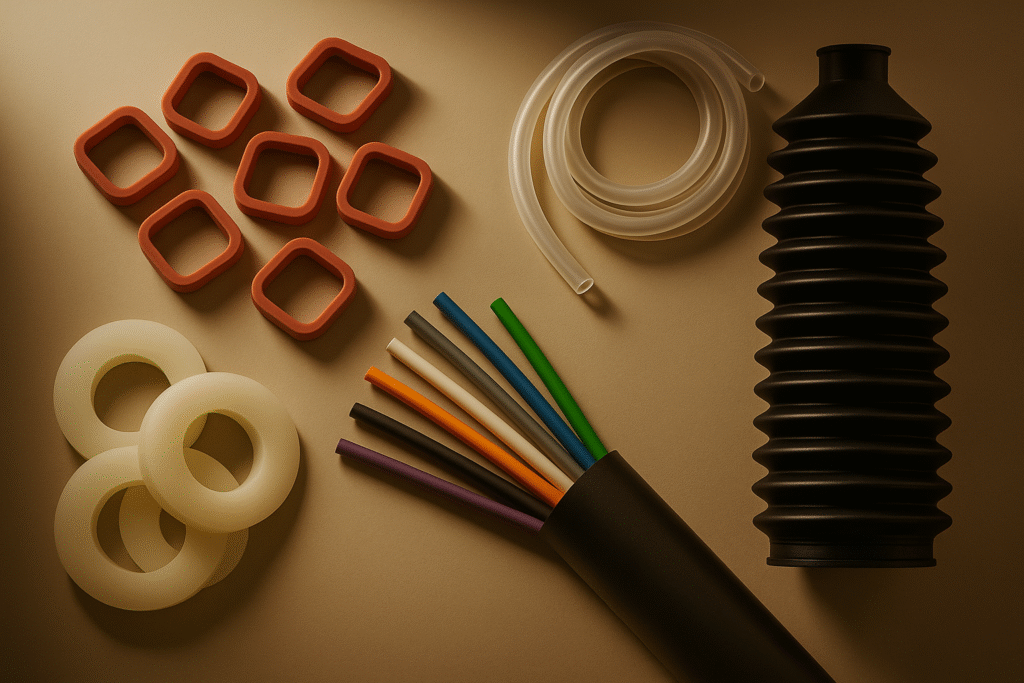

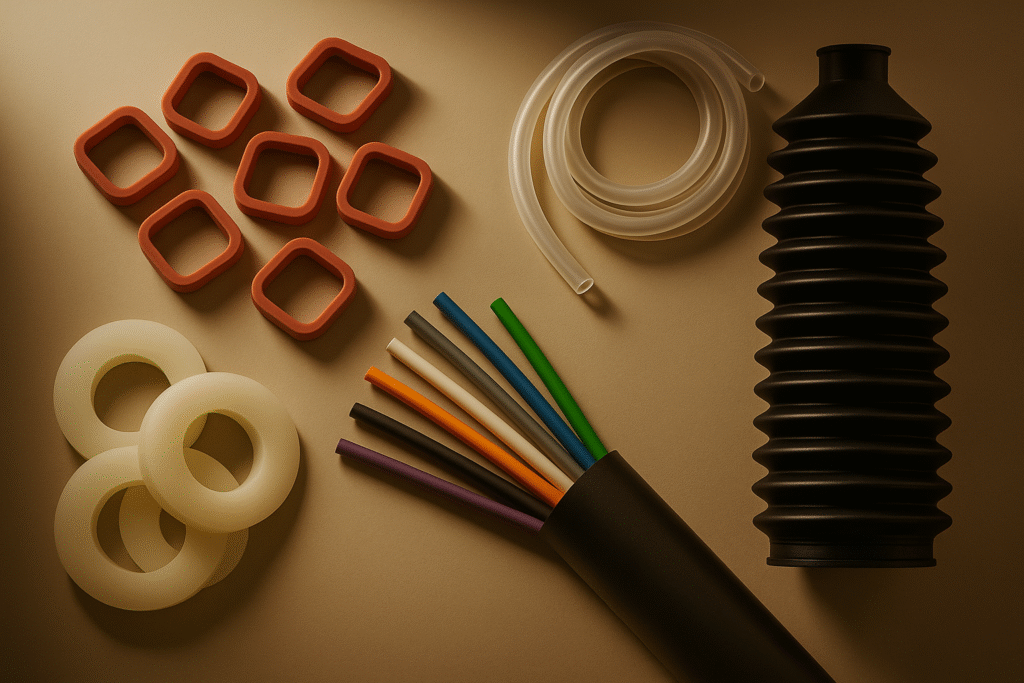

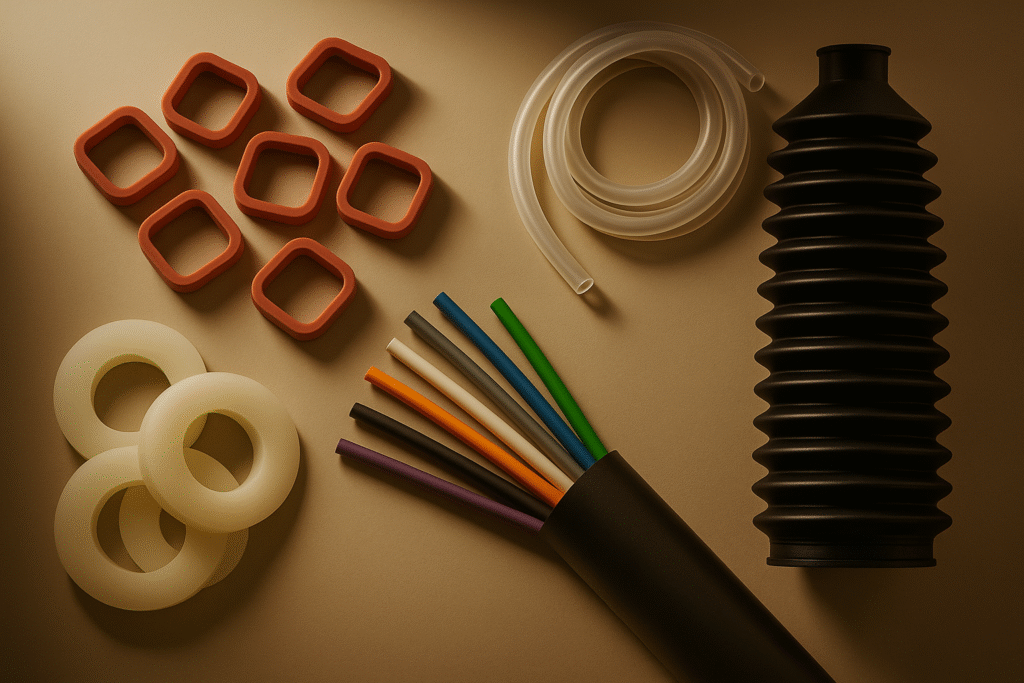

- Commonly used in injection molding, film extrusion, wire & cable coatings, and automotive plastic components, especially where precision and surface finish are crucial.

- Enhances processing by improving melt flow, reducing friction, minimizing die build-up, and enabling excellent mold release, which is critical for high-volume manufacturing.

- Improves final product performance by delivering smoother surfaces, better scratch resistance, and anti-stick properties, ensuring durability and visual appeal.

- Supports energy-efficient processing while preserving the mechanical strength, dimensional stability, and color integrity of the base polymer, making it an ideal choice for quality-focused industries.

Siloxane Masterbatch is a high-performance additive solution engineered to enhance the processing and functional properties of thermoplastics. Formulated with polysiloxane as the active ingredient, this masterbatch improves flowability, reduces friction, and minimizes surface defects such as sink marks and weld lines during molding or extrusion. It offers excellent lubrication and release characteristics, enabling smoother production cycles and higher output efficiency. In end applications, Siloxane Masterbatch imparts superior scratch resistance, abrasion resistance, and long-lasting surface finish, making it highly suitable for automotive components, electrical housings, packaging films, and consumer goods. Additionally, it contributes to improved mechanical properties, dimensional stability, and reduced wear on processing equipment, ultimately extending product life and lowering overall production costs.

Industries using SMB

automobile

industrial

electronics

packaging

healthcare

Siloxane masterbatch is a high-performance additive designed to improve the processability and surface properties of thermoplastics during manufacturing operations.Siloxane masterbatch is a high-performance additive designed to improve the processability and surface properties of thermoplastics during manufacturing operations.

| Product name | Details |

| SMB 50-32 | |

| SMB 50-32 | |

| SMB 50-32 | |

| SMB 50-32 | |

| SMB 50-32 | |

| SMB 50-32 |